If you buy your gravel bike from a bricks-and-mortar shop, you won’t ever need to consider how the bike arrived at the shop, as someone else will have dealt with the logistics, the unpacking and the Pre Delivery Inspection (PDI). But if you buy your bike from a mail-order only company like Canyon, your role is not only to ride the finished bike, but also to unpack, build and test-ride your new pride and joy. Whether it arrives with you in one piece or not is down to the skill of the design team who have overseen the box and packaging design. Although it’s not glamorous, Olly decided to look into the world of cardboard.

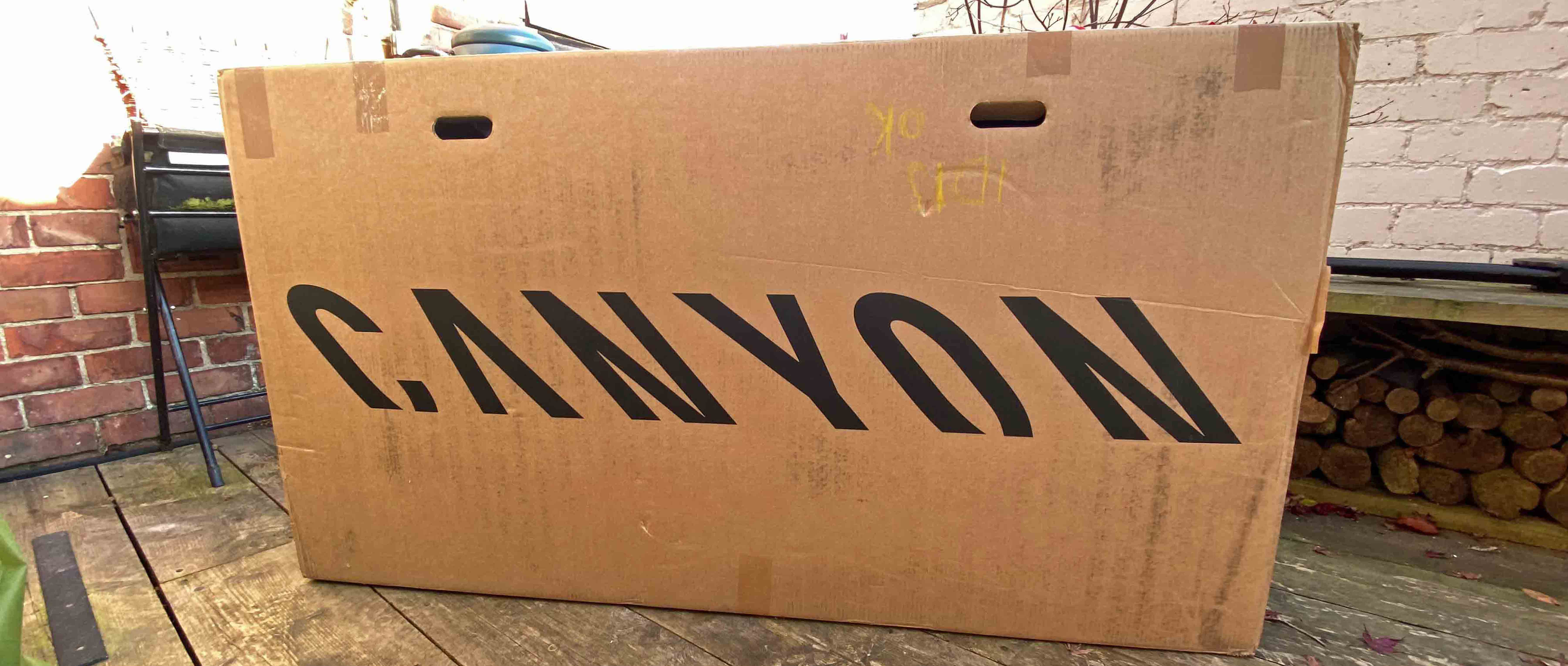

“I wasn’t supposed to have this box on my van today” said the slightly bemused courier “but some of my work colleagues decided I should be the lucky one to deliver it”. As we peered through the backdoors into the cavernous interior of the courier driver’s van, there was the usual organised chaos of cardboard boxes, but with one very definitely standing out from the rest. Right bang in the centre was a box at least three times larger than anything else. Although I couldn’t read the label on the end from where I stood, I knew this one was going to be for me. The box weighed 33 kg and stood 90 cm tall, 39 cm wide and 164 cm long. In short, it was the mother of all cardboard boxes.

Can you sign for this delivery please?

The courier helped me carry the box into my back yard and for a little while I just stood and stared. I’ve taken delivery of (and subsequently unboxed and built-up) a lot of bikes over the years, but this one was different. The box was significantly larger and heavier than anything I'd worked on before. I weighed it afterwards and the empty box (including the packaging) weighed 15 kg. What the hell was so big/heavy/precious that it needed a box like this? One of the new Canyon Grizl:ON gravel bikes was of course the answer. But this isn’t about the contents, this is about the packaging.

A handful of years ago, if you opened a cardboard bike box freshly delivered from the distributor, you would first of all need a pair of pliers to open the industrial-strength staples which held the top flaps shut. Then you would generally discover a mountain of single-use plastic packaging – foam padding, bubble wrap, air-filled bags and the like. Different manufacturers had their own preferred packing style, but the majority of boxes that I opened would result in you finding a lot of material that was destined for landfill.

Obviously, the number one priority for delivering a bike box to the customer (or the shop that is going to build it up) is to get it there in one piece. The box and packaging needs to protect the contents, but also do so in a way that’s as cost-effective and straightforward as possible to ship. This means (generally) making the box of standard dimensions and building in some carrying handles on both sides. Double-wall corrugated cardboard is the material of choice as it’s light, strong, relatively inexpensive and also, it’s simple to recycle pretty much everywhere. Bike boxes are pretty standard dimensions - 132cm x 18cm x 73cm is perhaps the most common. They weigh around 2kg, excluding any packaging materials.

Inspired by Apple?

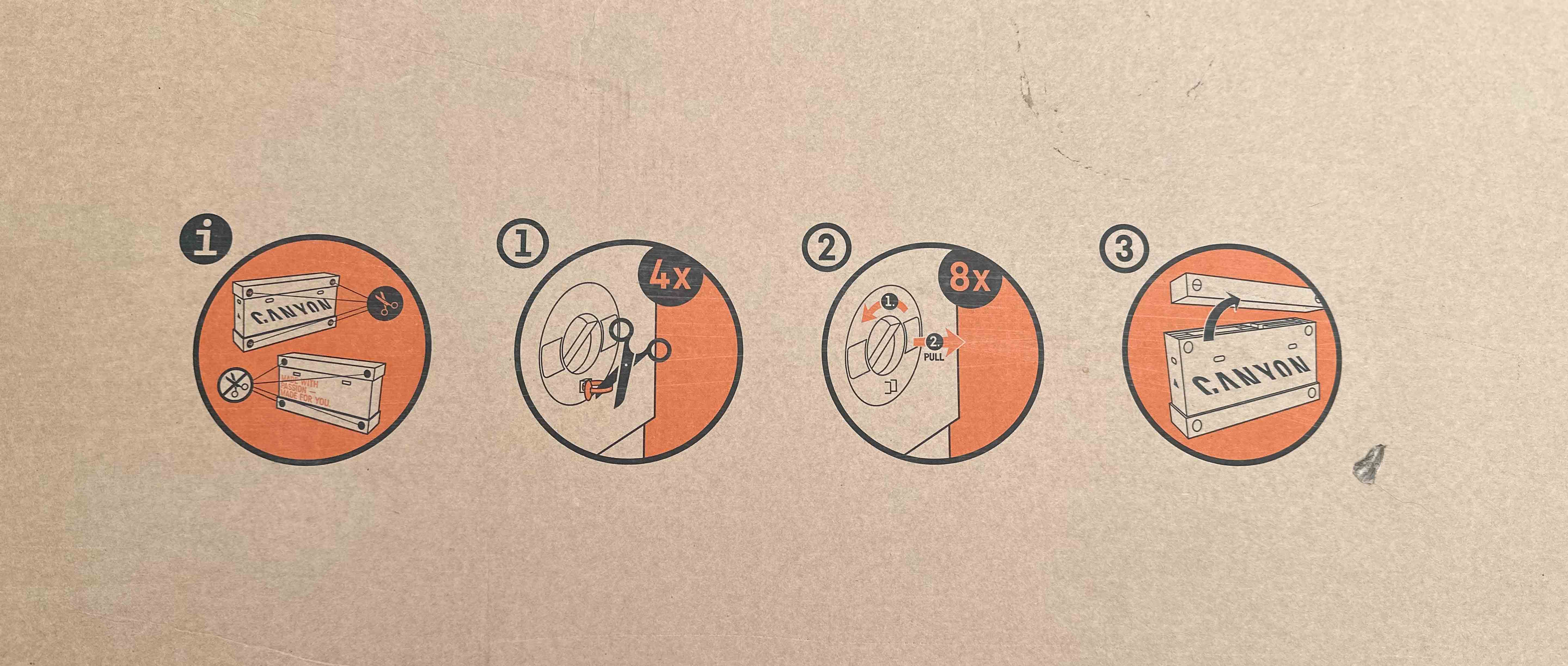

As soon I received the Grizl:ON box, it was obvious this wasn’t a ‘standard’ bike box. Even ignoring the oversized dimensions, the packaging comprised a top and bottom ‘lid’ which was held in place with reusable circular security fasteners. Each one was secured in place with a thin layer of transparent tape, presumably to prevent them from accidentally coming loose, but this seemed like a belt-and-braces approach as they were firmly fitted to the top and bottom on both sides. A printed set of instructions on the lid told me what to do – remove the zipties holding the fasteners in place (in my case, just peel the tape away), rotate the closers anti-clockwise 90 degrees and remove. The lid can then be lifted off.

When Apple launched their iconic and revolutionary iPhone in 2007 they applied for more than 200 patents. One of these was just for the packaging. Jony Ive, Apple’s former head of design once said "Steve [Jobs – Apple co-founder] and I spend a lot of time on the packaging. I love the process of unpacking something. You design a ritual of unpacking to make the product feel special. Packaging can be theatre." Canyon’s packaging is slightly more utilitarian than Apple’s, but the attention to detail is no less impressive

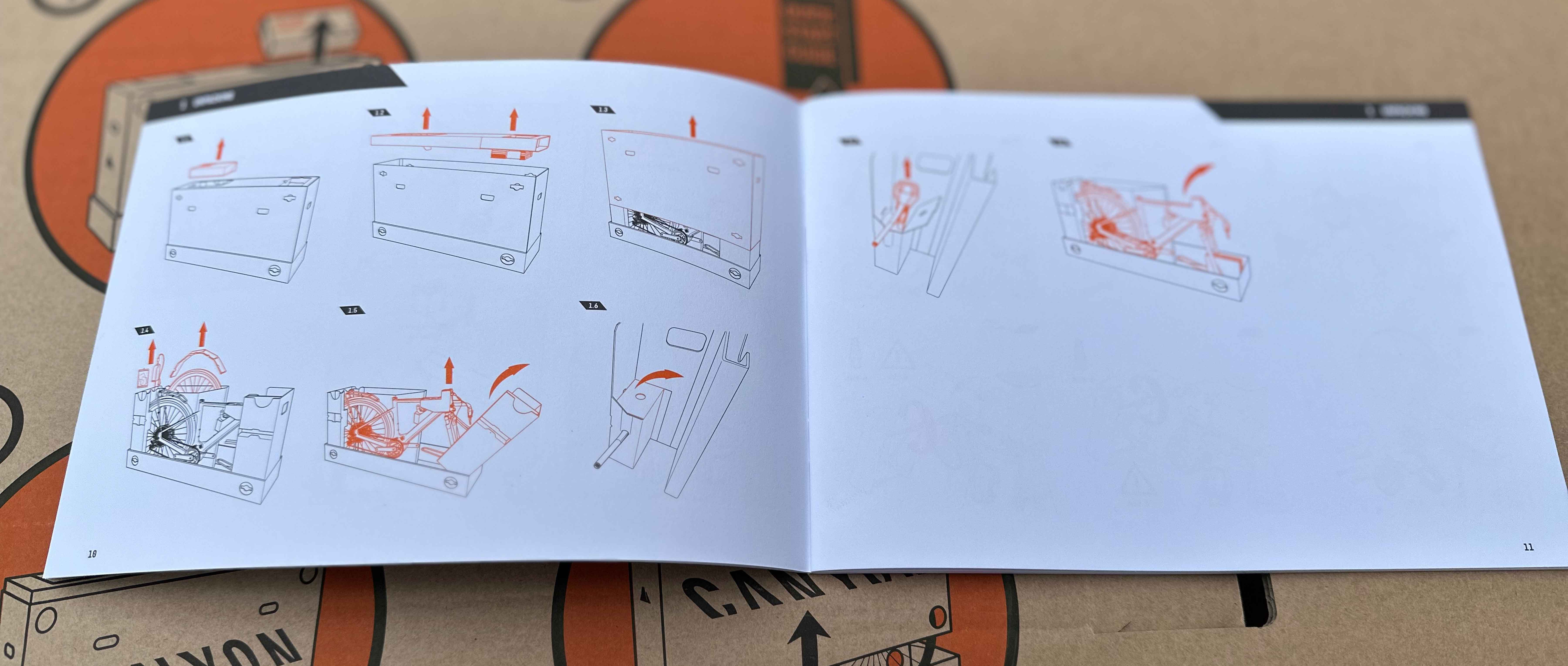

Once the lid has been removed, some simple but clever engineering/marketing means there’s a box embedded into the inside flap which contains a “Let’s get Started” box. This box contains all the tools, accessories and instructions that you need to build up your new bike.

Reduce, reuse, recycle.

What is most impressive about how the bike was packed is how little single-use plastic has been used. In total, there are just two small pieces of bubble wrap, two small pieces of thicker foam padding and one plastic bag. Everything else is constructed from cleverly engineered cardboard.

Canyon’s packaging designer is obviously a big fan of origami as there are carefully folded “boxes” to protect the brake levers, to hold the handlebar assembly against the top tube, to attach a large block of cardboard packaging/spacing to the rear wheel, as spacers in the front wheel, to encapsulate the front mudguard and finally as a spacer for the front forks. The vast majority of these don’t even have any sticky tape securing them – they are held in place via precision-cut tabs.

The chances are that 99% of bike buyers won’t even give two minute’s thought to how their new bike is actually packaged. What they will want to know is a) Will it get to me in one piece b) Will it be easy to unpack and build up c) How easy will it be to dispose of the packaging afterwards. The answer to all those questions would be positive. The bike arrived in pristine condition with not one single scratch/blemish/mark. Even the disc rotors were completely straight. It took me around 90 minutes to build up, which included photographing the process and tubelessing the tyres (the wheels and tyres are tubeless ready, but were fitted with tubes). And in terms of disposal, the vast majority of the packaging is cardboard so can be easily recycled. The sheer size of the box might mean you need to do quite a bit of chopping up before you can fit it in your recycling bin, or you might need to find a way to transport it to your local recycling centre, but at least you know the cardboard box and packing materials can be recycled.

So, what's next?

Somehow I’ve managed to write more than 1000 words about cardboard and haven’t even mentioned the bike yet. If you’d like to find out why we’ve got it and what we’re going to be using it for, you’ll have to wait a little while yet....